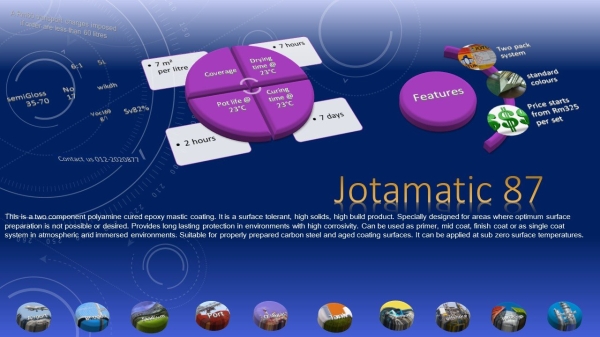

Jotamastic 87

Download Files

jotamastic_87.JPG (173.35 KB)

jotamastic_87.JPG (173.35 KB)

Safety_Precautions.pdf (177.69 KB)

Safety_Precautions.pdf (177.69 KB)

TDS.pdf (0.91 MB)

TDS.pdf (0.91 MB)

Brochure.pdf (1 MB)

Brochure.pdf (1 MB)

Description:

Two-Pack Primers

http://www.jotun.com/ww/en/b2b/technical-info/calculator/

The market leading two-pack epoxy primer in the marine industry. Steel where blast cleaning may not be possible and on hydrojetted surfaces still being moist where gloss and colour retention is of minor importance. Can be used alone or in combination with various systems of primers and topcoats. Gives excellent corrosion protection both in salt and fresh water. If exposed to sunlight chalking may occur.

Jotamastic 87 can be used as primer, mid coat and finish coat or as single coat system in atmospheric and immersed environments. It can be applied at sub zero surface temperatures.

Feature:

Durable maintenance solution for harsh environments

Well proven

Jotamastic 87 revolutionised the maintenance business when introduced more than 25 years ago, with an unprecedented track record.

Durable solution in harsh environments

Designed to provide long lasting protection in severe environments

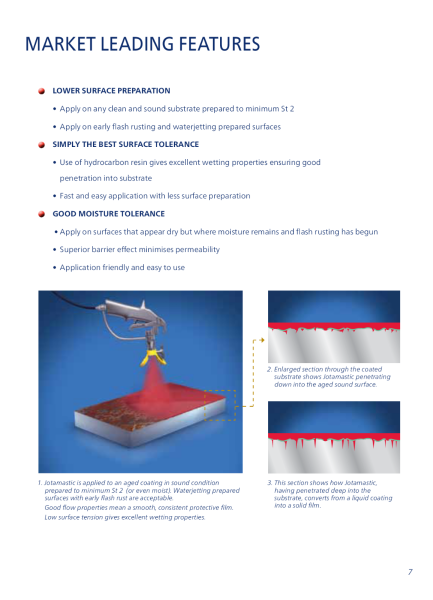

Surface Tolerant

Specially designed for areas where optimum surface preparation is not possible or desired, and therefor ideal for maintenance and repair.

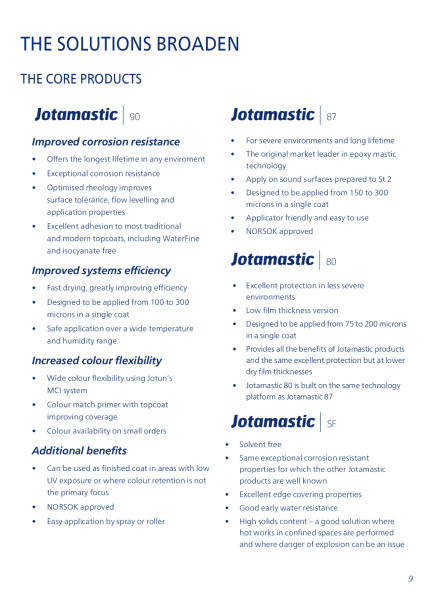

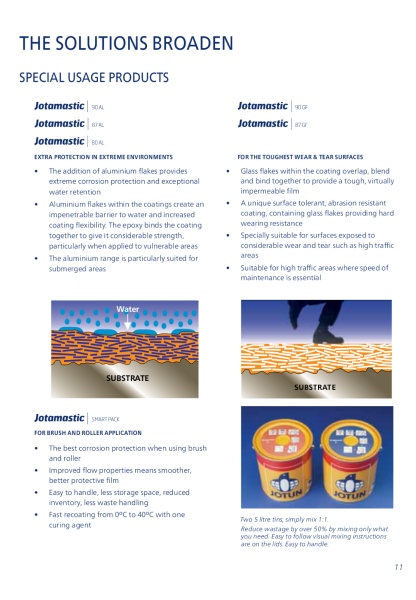

Variants

Jotamastic 87 offers a range of variants for special usage situations where further enhancement of key features is needed.

For use in a wide range of solutions

Surface tolerant for maintenance and repair

Jotamastic 87 revolutionised the maintenance business when introduced more than 25 years ago, with an unprecedented track record.

Durable solution in harsh environments

Designed to provide long lasting protection in severe environments

Surface Tolerant

Specially designed for areas where optimum surface preparation is not possible or desired, and therefor ideal for maintenance and repair.

Variants

Jotamastic 87 offers a range of variants for special usage situations where further enhancement of key features is needed.

- Aluminium: for extra barrier effect in extreme environments and Improved resistance to cathodic disbonding if direct to steel contact.

- Glass flake: for increased abrasion resistance

- MIO: micaceous iron oxide for increased barrier effect and abrasion resistance

For use in a wide range of solutions

- Direct to metal

- As midcoat on zinc primers

- Immersed service

Surface tolerant for maintenance and repair

- More than 25 years track record

- For severe environments requiring long liftetime expectancy

Available 5L pack.

| Application method : | Brush, roller, conventional air spray, high pressure airless spray | ||

| Drying time : | 6 hours @ 23c | ||

| Coverage : | 6-8 sq. metres per litre using brush or roller | ||

| Coats: | 2 | ||

| Thinner : | No 17 | ||

| Water resistance : | Excellent | ||

| Flexibility : | Good | ||

| Gloss level : | Semi-Gloss | ||

| Gloss retention : | Limited | ||

| Chemical Resistance : | Very Good | ||

| Abrasion Resistant | Very Good | ||

| Solvent Resistant | Good | ||

| Pot Life | 2 hours @23c | ||